Stainless Steel Low-Speed Crusher with Auto-Recycling & Soundproof Design

Designed for durability and high efficiency, the low-speed pulverizer adopts a refined steel body, automatic recovery fan, double-layer soundproof cabinet, and pure copper core motor. It is suitable for gentle pulverization in industries such as crops and plastic recycling, achieving quiet and dust-free operation.

Order(MOQ):

1ProductOrigin:

Huizhou, ChinaColor:

WhiteShippingPort:

Shenzhen, ChinaLeadTime:

15 DaysBrand:

PQProduct Description

The PQ low-speed pulverizer adopts a heavy-duty fine steel frame and a pure copper core motor, which is sturdy and durable. The built-in automatic recovery fan collects the crushed particles in real time and can be directly transported to the supporting storage system, realizing seamless material processing and reducing manual intervention. The double-layer soundproof cabinet and the sealed crushing chamber effectively isolate noise and dust, meeting the strict environmental safety standards of clean workshops. The humanized control panel integrates a time relay to support customized crushing cycles. Whether it is food additive processing or plastic waste recycling, this machine can provide a reliable and efficient crushing solution.

Product Parameters

| Model | YS-LS-2000 | YS-LS-3000 | YS-LS-5000 |

| Number of Blades | 8 knives (8*3) 24 pieces |

10 knives (10*3) 30 pieces |

14 knives (14*3) 42 pieces |

| Motor Power | 2.2kW | 2.2kW | 3.7kW |

| Spindle Speed (r/min) |

140 | 140 | 140 |

| Blade Material | SKD-11 | SKD-11 | SKD-11 |

| Feeding Port Size (mm) |

320*255 | 320*255 | 320*430 |

| Grinding Amount | 50-100kg/h | 75-150kg/h | 100-200kg/h |

| Screen Hole Diameter (mm) |

6 | 6 | 6 |

| Operating Volume (dB) |

65 | 65 | 65 |

| Weight (Excluding Fan) |

170kg | 184kg | 229kg |

| Machine Size (cm) |

90*60*141 | 90*60*145.5 | 120*60*151.5 |

| Machine Size Excluding Bell Mouth (cm) |

90*60*127.5 | 90*60*132 | 120*60*138 |

| Grinding Chamber Outside Bell Mouth |

485*420 | 485*420 | 480*600 |

| 280*250 | 280*305 | 280*425 |

Key Features

✅ Stainless Steel Construction for Durability: Built with high-strength stainless steel, the crusher resists wear and impact, ensuring long-term reliability even under frequent heavy-duty operations—ideal for processing fibrous or tough materials.

✅ Automatic Recycling Fan for Efficiency: Integrated fan system collects crushed materials in real time and transports them to designated containers, eliminating manual cleanup and reducing dust for seamless integration with automated production lines.

✅ Double-Layer Soundproof Enclosure: The sealed, sound-insulated housing minimizes operational noise, creating a quiet workspace that meets strict noise standards in pharmaceutical, food, and other sensitive industries.

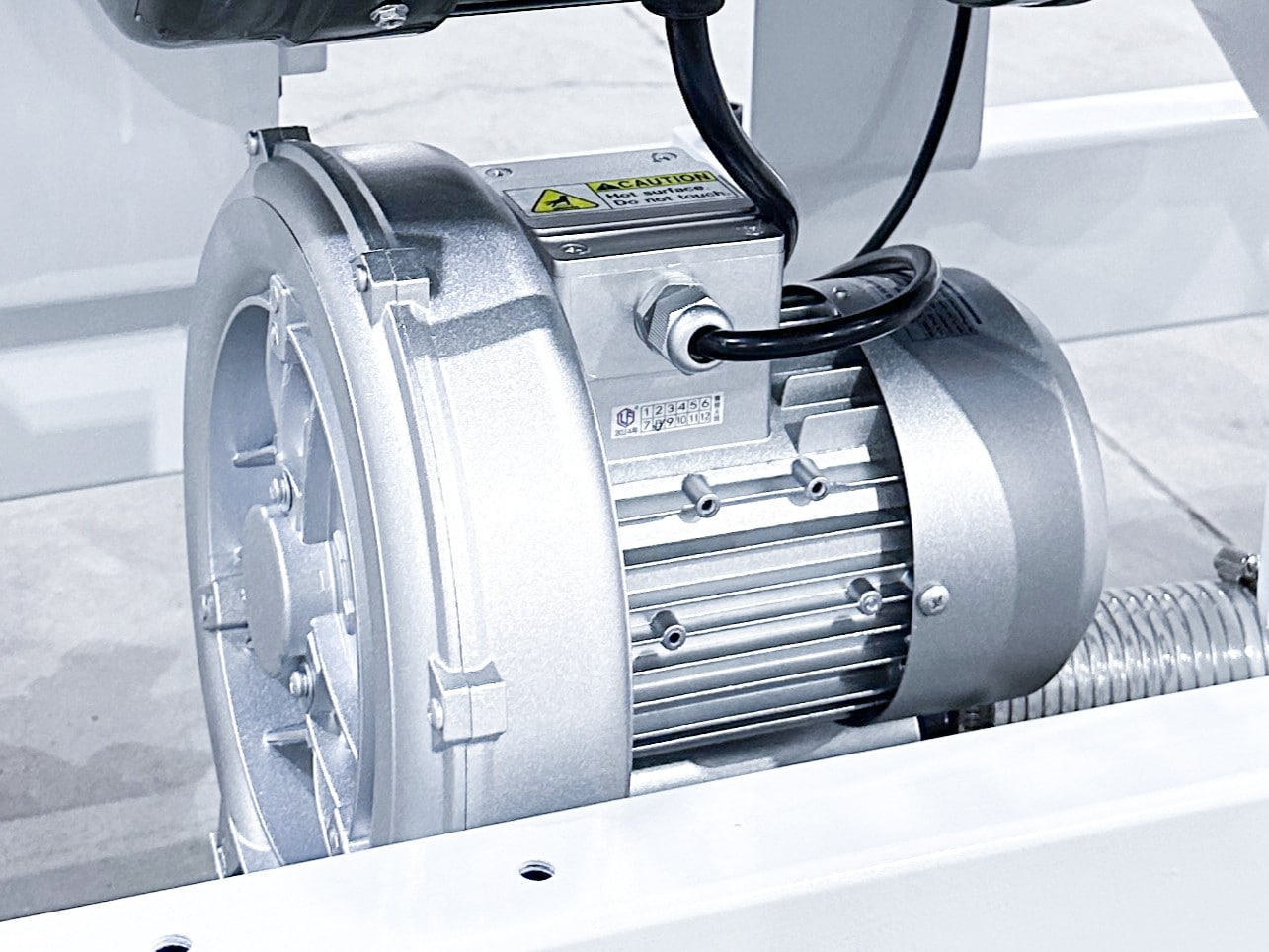

✅Pure Copper Motor for Stable Performance: The pure copper motor offers excellent conductivity and heat dissipation, delivering consistent high torque for efficient crushing of soft plastics, fibers, and more, reducing motor overheating risks.

✅Time Relay for Customizable Operation: Equipped with a time relay device, it supports customizing the crushing time and interval to avoid over-crushing or insufficient efficiency.

✅Visual window: The machine body is equipped with an explosion-proof visual window to observe the material status and particle size in the crushing chamber in real time.

✅Flexible adaptation of the recycling system: It supports seamless connection with the external recycling system, and can customize the crushing and recycling plan to meet the needs of different working conditions.

Product Detail Display

CAN BE PAIRED WITH A RECYCLING SYSTEM

Hard and soft materials can be crushed into powder with low noise.

Strong crushing ability, safe and stable operation.

Matching Scheme ①

Cyclone Recovery System

+

High-Pressure Blower

Matching Scheme ②

Two-Material Proportional Valve

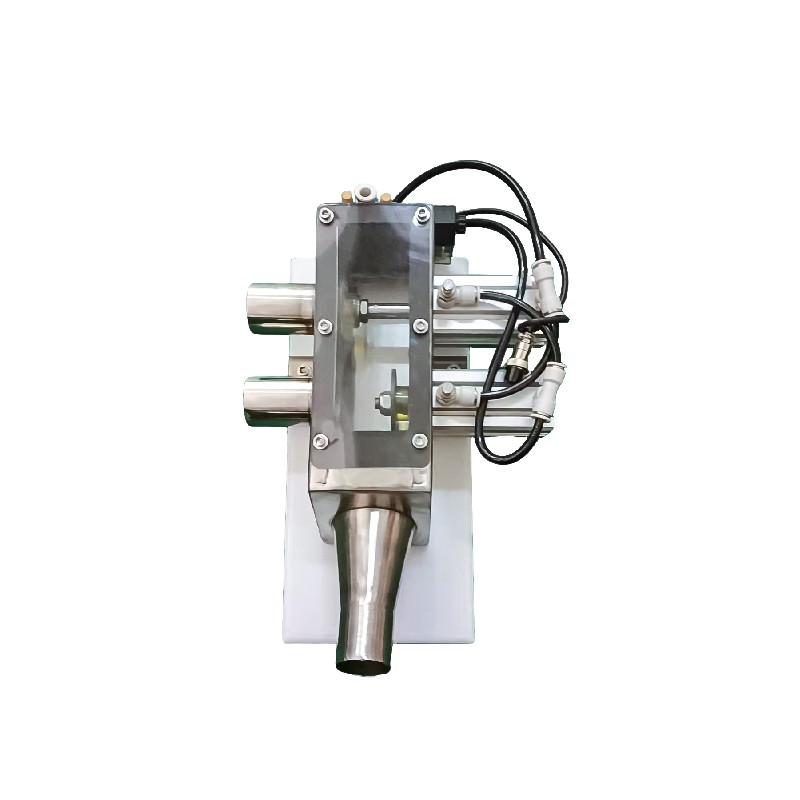

AUTOMATIC RECOVERY FAN

The optional recovery fan can automatically transport the crushed materials

to the production equipment to reduce labor costs.

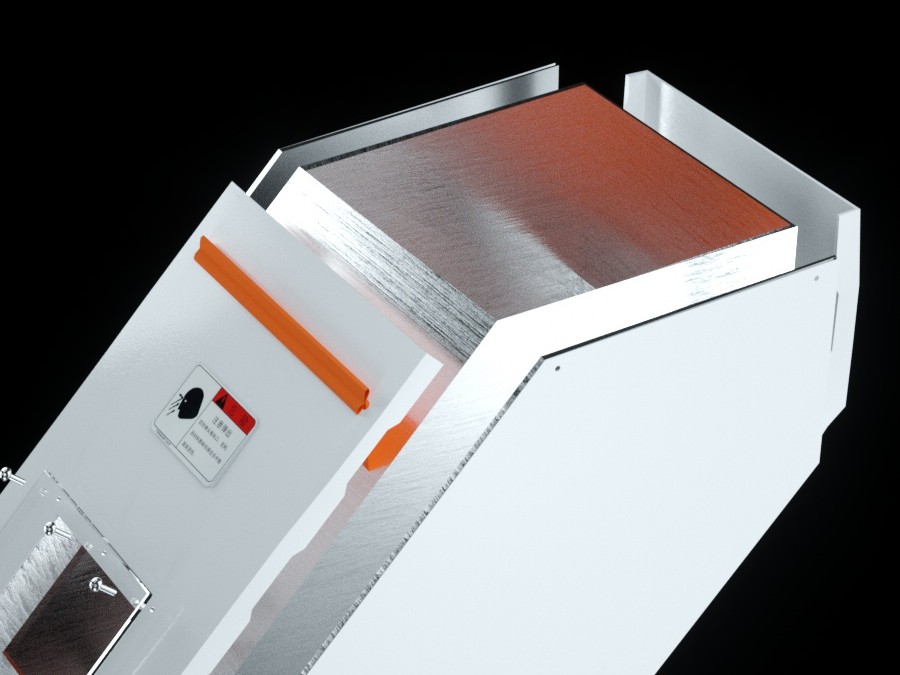

DOUBLE-LAYER SOUNDPROOF BOX

The crushing box is made of thickened stainless steel

to greatly reduce the crushing noise.

▶Yes, we are a manufacturer with over 10 years of experience.

2) How can I place an order?

▶You can contact us by email about your order details or place an order online.

3) What's the order procedure?

▶We issue you a Proforma Invoice after you confirm the order. And then you pay the deposit before we go into production. It usually takes 7-15 days for production. We will contact you for shipment details and the balance payment when the machine is ready. After payment has been settled, we will ship out the machine.

4) How can I pay you?

▶You can make payment by T/T (telegraphic transfer), Western Union, Moneygram, and L/C.

5) Do you have a manual for the machine?

▶Yes, of course. It is in the English version. We will send it with the machine.

6) Can you offer us the necessary paperwork for customs clearance?

▶Yes, of course. We will send you all the papers you need.

Copyright @2024 Pengqiang Intelligent Technology Group (Guangdong) Co., Ltd.

Network Supported

Network Supported