Designed for hygroscopic engineering plastics like PA, PET, and PC, this Three-in-One Dehumidification & Drying Machine uses -40°C dew point dry air in a closed-loop system to efficiently remove both surface and core moisture from plastic pellets, stabilizing moisture content below 0.02%. It eliminates common molding defects—shrinkage, silver streaks, bubbles, and poor transparency—in injection molding and extrusion processes, while reducing energy consumption by 35% compared to traditional hot air dryers. The ultimate solution for high-precision plastic processing.

Order(MOQ):

1ProductOrigin:

Huizhou, ChinaColor:

WhiteShippingPort:

Shenzhen, ChinaLeadTime:

15 DaysBrand:

PQProduct Description

In the field of precision plastic processing, defects such as shrinkage, silver streaks, and bubbles caused by incomplete drying of hygroscopic raw materials such as PA, PET, and PC not only cause a scrap rate of more than 30%, but also frequently cause delivery delays and customer complaints. Traditional hot air dryers can only handle surface moisture and are helpless against moisture absorption inside the particles, until the emergence of three-in-one dehumidification dryers.

The three-in-one dehumidifying dryer is equipped with a closed-loop deep dehumidification system, which penetrates the core of the particles through ultra-dry air with a dew point of -40℃, accurately controls the moisture content to below 0.02%, and cuts off the cause of defects from the source.

It is especially suitable for production scenarios such as new energy vehicle parts and electronic precision parts that require strict material stability.

Product Parameters

| Specifications | 25kg | 50kg | 75kg | 100kg | 150kg | 200kg | Notes |

| Power Supply Voltage | 3¢ 380V | 3¢ 380V | 3¢ 380V | 3¢ 380V | 3¢ 380V | 3¢ 380V | |

| Frequency | 50HZ | 50HZ | 50HZ | 50HZ | 50HZ | 50HZ | |

| Drying Barrel Capacity (L) | 25 | 50 | 75 | 100 | 150 | 200 | Optical Grade |

| Dehumidification Air Volume (m³/hr) | 30 | 50 | 80 | 100 | 120 | 200 | Dew Point: -40°C |

| Drying Electric Heating Power (kW) | 2.7 | 4 | 4 | 6 | 8 | 12 | |

| Drying Fan Power (kW) | 0.37 | 0.37 | 0.37 | 0.55 | 1.1 | 1.5 | TIANTAI |

| Regeneration Electric Heating Power (kW) |

2 | 2 | 2.7 | 3.5 | 4 | 5 | |

| Regeneration Fan Power (kW) | 0.18 | 0.18 | 0.18 | 0.25 | 0.25 | 0.37 | TIANTAI |

| Feeding Fan Power (kW) | 0.75 | 1.1 | 1.1 | 1.1 | 1.1 | 1.5 | TIANTAI |

| Rotary Motor (W) | 15 | 15 | 15 | 15 | 15 | 15 | |

| Total Machine Power (kW) | 6 | 7.65 | 8.35 | 11.4 | 14.45 | 20.37 | |

| Computer Controller | SF877000A | / | / | / | / | / | Bangpu, Optional 879001A |

| Contactor | LC1N | / | / | / | / | / | Schneider |

| Thermal Overload Relay | LRN | / | / | / | / | / | Schneider |

| Main Power Switch | GLD11 | / | / | / | / | / | Gree |

| Stainless Steel Micro-Motion Bucket | 7.5L | / | / | / | / | / | |

| Photoelectric Bucket | 7.5L | / | / | / | / | / | Photoelectric Sensor: FOTEK |

| Vacuum Suction Box | 1 | 1 | 1 | 1 | 1 | 1 | 38# 51# |

| Disconnection Type Suction Box | 1 | 1 | 1 | 1 | 1 | 1 | 38# 51# |

| Cooler | 1 | 1 | 1 | 1 | 1 | 1 | Water-Cooled |

| Overall Dimensions (mm) | 650*1150*1400 | 650*1150*1520 | 650*1150*1620 | 730*1330*1620 | 730*1330*1980 | 840*1430*2400 | |

| Pipe (M) | 8 | 10 | 10 | 10 | 12 | 12 | 38# 51# |

| Specifications | 300kg | 400kg | 600kg | 800kg | 1000kg | Notes |

| Power Supply Voltage | 3¢ 380V | 3¢ 380V | 3¢ 380V | 3¢ 380V | 3¢ 380V | |

| Frequency | 50HZ | 50HZ | 50HZ | 50HZ | 50HZ | |

| Drying Barrel Capacity (L) |

300 | 400 | 600 | 800 | 1000 | Optical Grade |

| Dehumidification Air Volume (m³/hr) | 300 | 400 | 500 | 700 | 800 | Dew Point: -40°C |

| Drying Electric Heating Power (kW) | 15 | 18 | 22 | 25 | 28 | |

| Drying Fan Power (kW) | 2.2 | 3 | 4 | 4.5 | 5 | TIANTAI |

| Regeneration Electric Heating Power (kW) | 8 | 10 | 10 | 12 | 15 | |

| Regeneration Fan Power (kW) | 0.55 | 0.75 | 1.1 | 1.5 | 2.2 | TIANTAI |

| Feeding Fan Power (kW) | 1.5 | 2.2 | 2.2 | 2.2 | 3 | TIANTAI |

| Rotary Motor (W) | 15 | 15 | 15 | 25 | 25 | |

| Total Machine Power (kW) | 27.25 | 33.95 | 39.45 | 45.45 | 53.45 | |

| Computer Controller | / | / | / | / | / | Bangpu, Optional 879001A |

| Contactor | / | / | / | / | / | Schneider |

| Thermal Overload Relay |

/ | / | / | / | / | Schneider |

| Main Power Switch | / | / | / | / | / | Gree |

| Stainless Steel Micro-Motion Bucket | / | 12L | 12L | 24L | 24L | |

| Photoelectric Bucket | / | / | / | 12L | 12L | Photoelectric Sensor: FOTEK |

| Vacuum Suction Box | 1 | 1 | 1 | 1 | 1 | 38# 51# |

| Disconnection Type Suction Box | 1 | 1 | 1 | 1 | 1 | 38# 51# |

| Cooler | 1 | 1 | 1 | 1 | 1 | Water-Cooled |

| Overall Dimensions (mm) | 900**1630*2200 | 900*1630*2460 | 1220*2150*2560 | 1400*2300*3200 | 1640*2600*3320 | |

| Pipe (M) | 12 | 12 | 12 | 18 | 18 | 38# 51# |

Key Features

✅ Three-in-One Integration: Dehumidify, dry, and feed materials in one step.

✅ Built for Demanding Environments: Corrosion-resistant & high-temperature durable for 24/7 operation.

✅ Deep Dehumidification: -40℃ dry air penetrates pellets to extract hidden moisture.

✅ Energy-Efficient Loop: Sealed circulation cuts heat loss, saving 30 %+ energy.

✅ Gentle on Materials: Precise temperature control protects heat-sensitive plastics.

✅ Energy-Saving & Durable: Heat recovery reduces energy use; industrial-grade materials ensure longevity.

Product Detail Display

HIGH-QUALITY COMPONENTS FOCUS ON QUALITY

Make better quality to make customers feel more at ease.

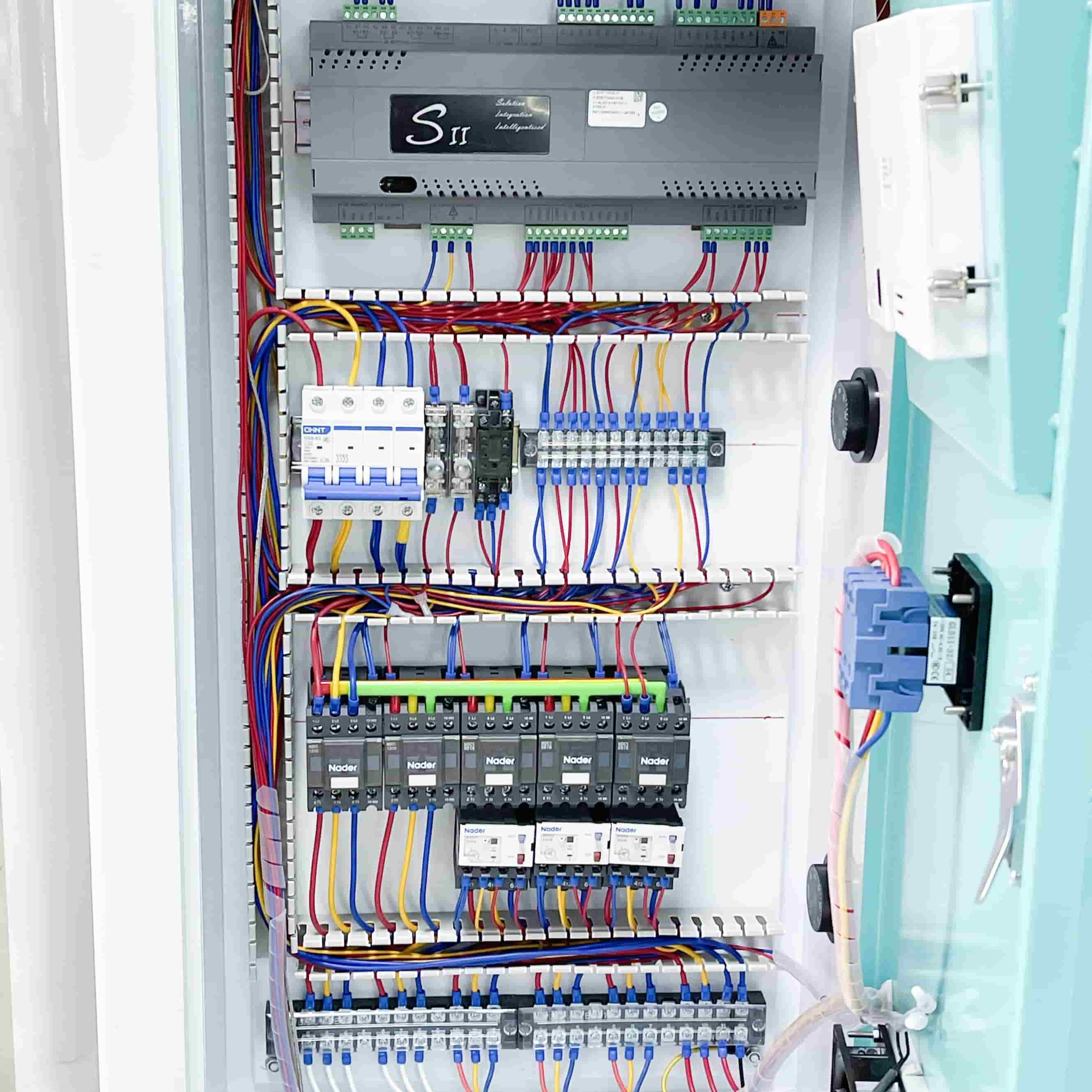

Brand Schneider Contactor

Clear Internal Circuit Structure

Stable Operation

Multiple Protections

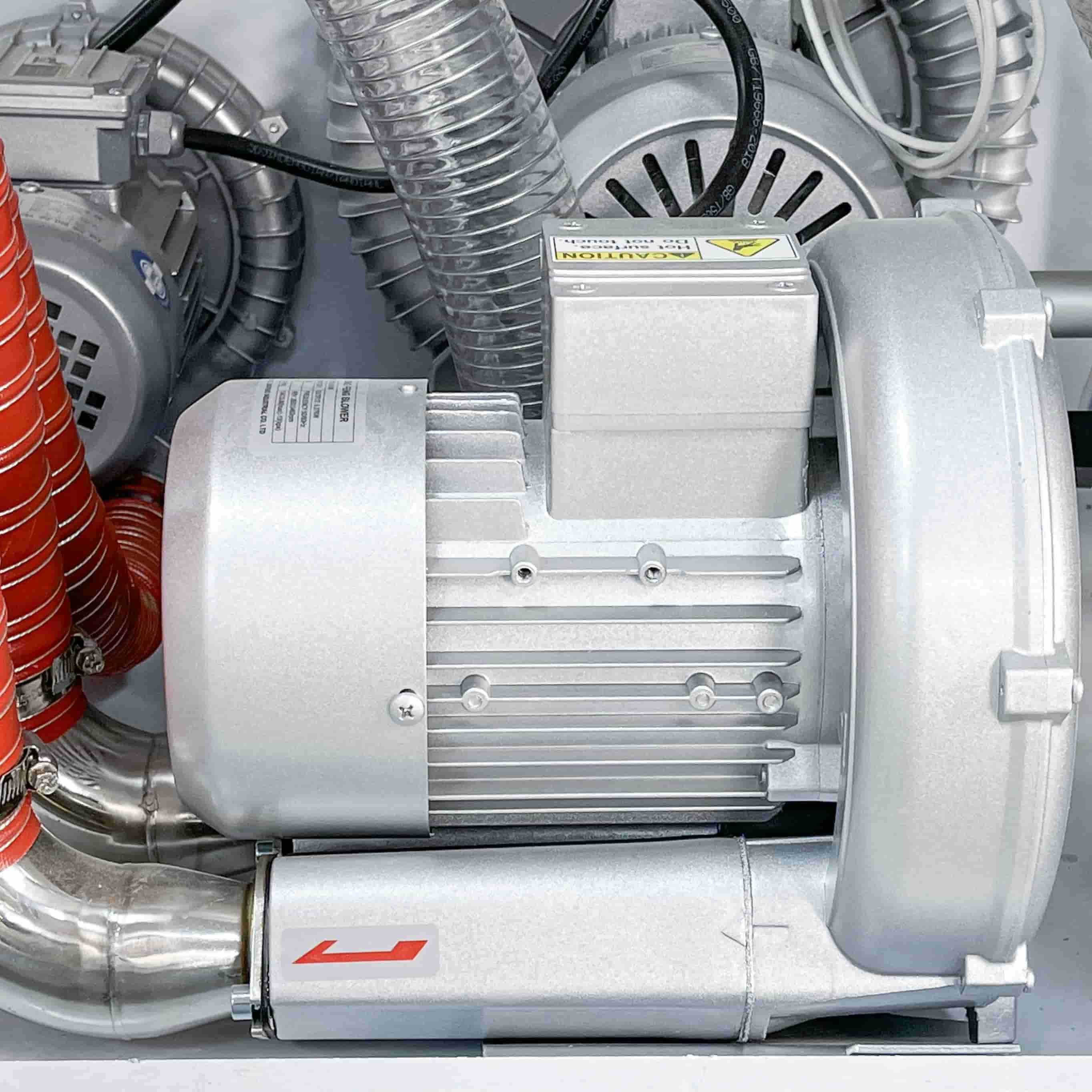

Built-In Three High-Pressure Fans

Quick Operation

Without Manual Work

Stable and Durable

MICROCOMPUTER CONTROL PANEL

The system has a regeneration temperature setting and an actual temperature display screen.

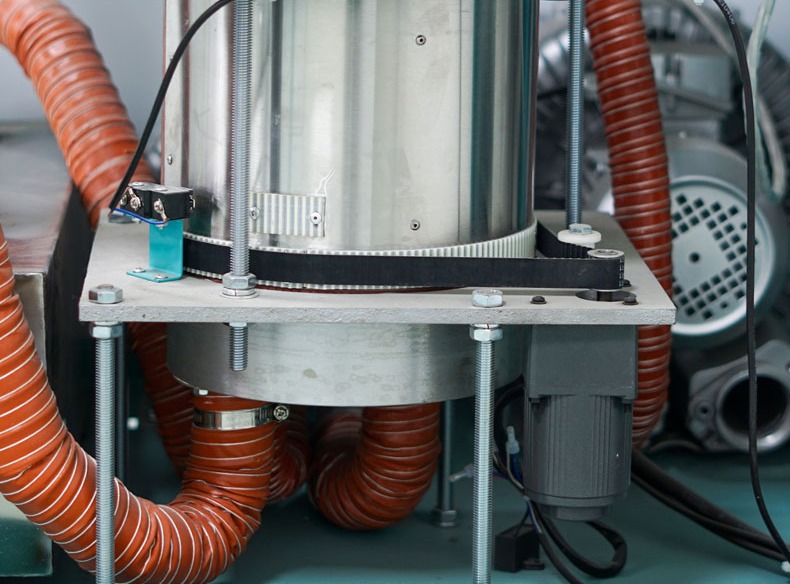

HONEYCOMB ROTOR DESIGN

No switching action to produce a dew point oscillation problem.

The honeycomb rotor has an adjustable speed,

and the dew point temperature can be lower than -40℃.

FAQ

▶Yes, we are a manufacturer with over 10 years of experience.

2) How can I place an order?

▶You can contact us by email about your order details or place an order online.

3) What's the order procedure?

▶We issue you a Proforma Invoice after you confirm the order. And then you pay the deposit before we go into production. It usually takes 7-15 days for production. We will contact you for shipment details and the balance payment when the machine is ready. After payment has been settled, we will ship out the machine.

4) How can I pay you?

▶You can make payment by T/T (telegraphic transfer), Western Union, Moneygram, and L/C.

5) Do you have a manual for the machine?

▶Yes, of course. It is in the English version. We will send it with the machine.

6) Can you offer us the necessary paperwork for customs clearance?

▶Yes, of course. We will send you all the papers you need.

Copyright @2024 Pengqiang Intelligent Technology Group (Guangdong) Co., Ltd.

Network Supported

Network Supported