High-Efficiency Water-Cooled Screw Chiller – Industrial-Grade Cooling with Smart Control

Designed specifically for large-scale industrial cooling, the water-cooled screw chiller uses a high-efficiency screw compressor, an intelligent temperature control system and durable heat exchange components to provide stable low-temperature support for chemical reactors, injection molding machines, data centers and other scenarios, while combining low energy consumption with easy maintenance.

Order(MOQ):

1ProductOrigin:

Huizhou, ChinaColor:

Black/WhiteShippingPort:

Shenzhen, ChinaLeadTime:

15 DaysBrand:

PQProduct Description

In response to the stringent cooling requirements of industrial processes, water-cooled screw chillers use high-performance twin-screw compressors, which save more than 40% energy compared to traditional models. The PLC intelligent control system achieves precise temperature control (±0.5°C accuracy) and real-time monitoring of parameters. The fully welded shell and tube condenser and evaporator are corrosion-resistant and anti-scaling, and can maintain long-term efficient operation even when dealing with hard water or corrosive media. Safety protection devices (high and low pressure protection, antifreeze switch, overload relay) reduce the risk of downtime, and the modular design facilitates the maintenance of key components. Whether cooling injection molds, controlling chemical reaction temperatures, or adjusting data center servers, this machine supports critical industrial operations with stable and reliable performance.

Product Parameters

| Parameters | Model | 40HP | 50HP | 60HP | 80HP | 100HP | 120HP |

| Cooling Capacity | X1000 Kcal | 100 | 125 | 150 | 200 | 250 | 300 |

| kW/h | 132 | 165 | 198 | 264 | 330 | 396 | |

| Power Supply | 3N-380V 50Hz/60Hz | ||||||

| Rated Current | A | 93.9 | 116 | 154 | 191.5 | 218.1 | 277.7 |

| Total Power | kW | 30 | 37.5 | 45 | 60 | 75 | 90 |

| Compressor | Type | Semi-Enclosed Screw Type | |||||

| Power (kW) | 30 | 37.5 | 45 | 60 | 75 | 90 | |

| Energy Regulation | 0-25%-50%-75%-100% | ||||||

| Condenser | Type | Shell and Tube Type | |||||

| Pipe Diameter (DN) | 80 | 100 | 100 | ||||

| Evaporator | Type | Shell and Tube Type | |||||

| Cold Water Volume (m³/h) |

24 | 25.8 | 37.8 | 48.2 | 56.8 | 68.8 | |

| Inlet and Outlet Water Diameter (DN) | 80 | 100 | |||||

| Machine Size | L (cm) | 240 | 265 | 275 | 320 | 320 | 320 |

| W (cm) | 100 | 100 | 100 | 110 | 120 | 120 | |

| H (cm) | 130 | 130 | 135 | 150 | 150 | 160 | |

| Unit Weight | Kg | 900 | 1100 | 1200 | 1300 | 150 | 1700 |

| Operating Weight | Kg | 1350 | 2100 | 3300 | 3300 | 3750 | 4000 |

| Parameters | Model | 150HP | 160HP | 180HP | 200HP | 240HP | 280HP |

| Cooling Capacity | X1000 Kcal | 375 | 400 | 450 | 500 | 600 | 700 |

| kW/h | 495 | 528 | 594 | 660 | 792 | 924 | |

| Power Supply | 3N-380V 50Hz/60Hz | ||||||

| Rated Current | A | 320.1 | 344.1 | 398.5 | 444.2 | 507.3 | 581.3 |

| Total Power | kW | 112.5 | 120 | 135 | 150 | 180 | 210 |

| Compressor | Type | Semi-Enclosed Screw Type | |||||

| Power (kW) | 56.25×2 | 60×2 | 67.5×2 | 75X2 | 90X2 | 105X2 | |

| Energy Regulation | 0-25%-50%-75%-100% | ||||||

| Condenser | Type | Shell and Tube Type | |||||

| Pipe Diameter (DN) | 125 | 150 | 200 | ||||

| Evaporator | Type | Shell and Tube Type | |||||

| Cold Water Volume (m³/h) |

84.3 | 87.7 | 108.4 | 117 | 135.9 | 155 | |

| Inlet and Outlet Water Diameter (DN) |

125 | 150 | 200 | ||||

| Machine Size | L (cm) | 330 | 330 | 350 | 350 | 360 | 400 |

| W (cm) | 130 | 130 | 130 | 130 | 140 | 150 | |

| H (cm) | 170 | 170 | 180 | 180 | 210 | 220 | |

| Unit Weight | Kg | 2000 | 2300 | 2600 | 2900 | 3200 | 3800 |

| Operating Weight | Kg | 4500 | 4800 | 5200 | 5500 | 5800 | 7000 |

Key Features

✅ Thickened Insulation Cotton: Use high-density thickened insulation material to wrap key components, effectively reduce pipeline cooling loss, reduce operating costs, and ensure continuous and efficient operation of the equipment.

✅ Refrigerant Pressure Gauge: Equipped with a high-precision refrigerant pressure gauge, it displays the system pressure changes, which is convenient for operators to intuitively grasp the operating status and improve the convenience and safety of equipment maintenance.

✅Emerson Filter: Built-in, well-known brand dry filter, effectively removes moisture and impurities in the refrigerant, protects core components such as compressors and valves, and reduces the risk of failure.

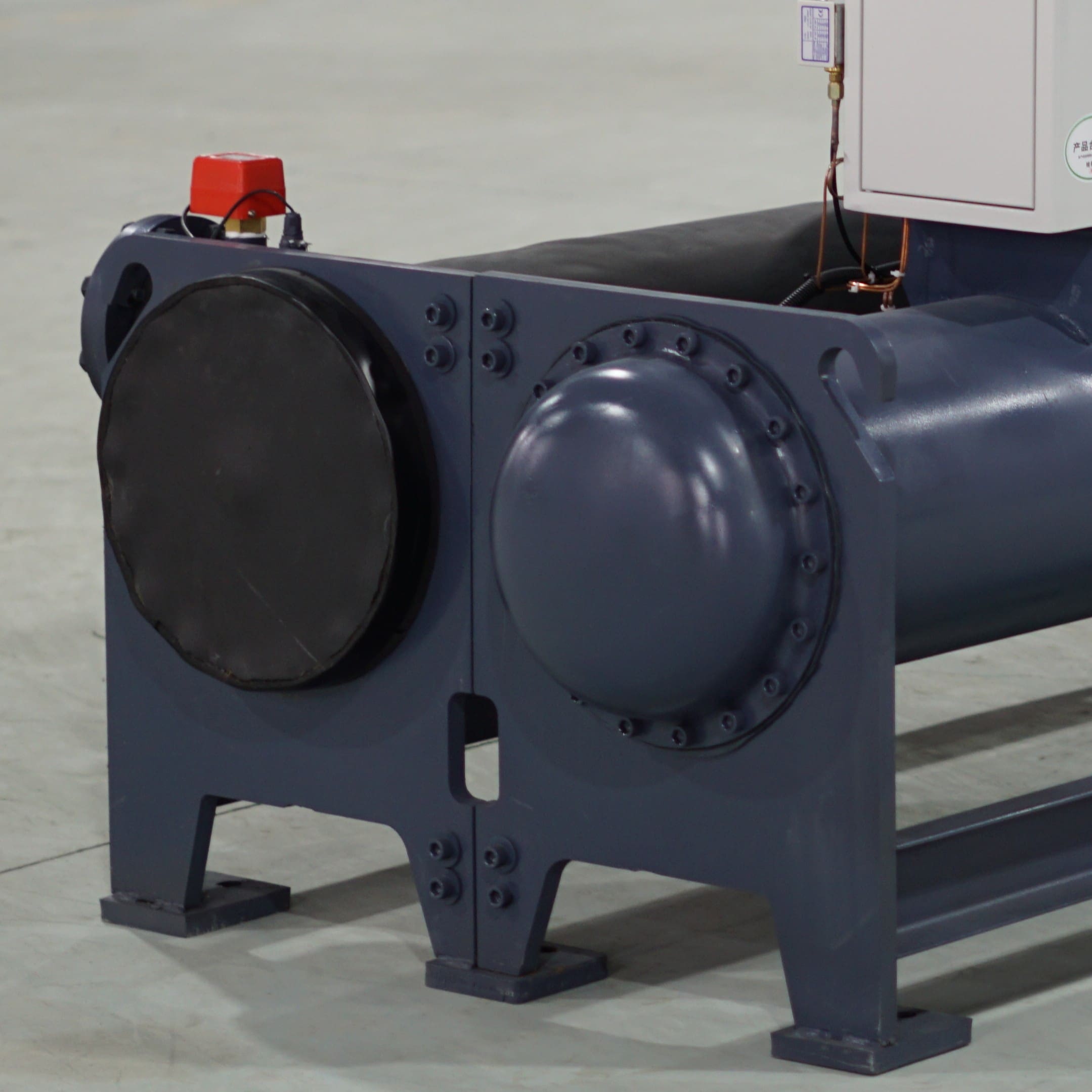

✅Shell and Tube Evaporator: The all-copper shell and tube evaporator design is resistant to high pressure and impact, and is suitable for a variety of cooling media to ensure long-term stable heat exchange performance.

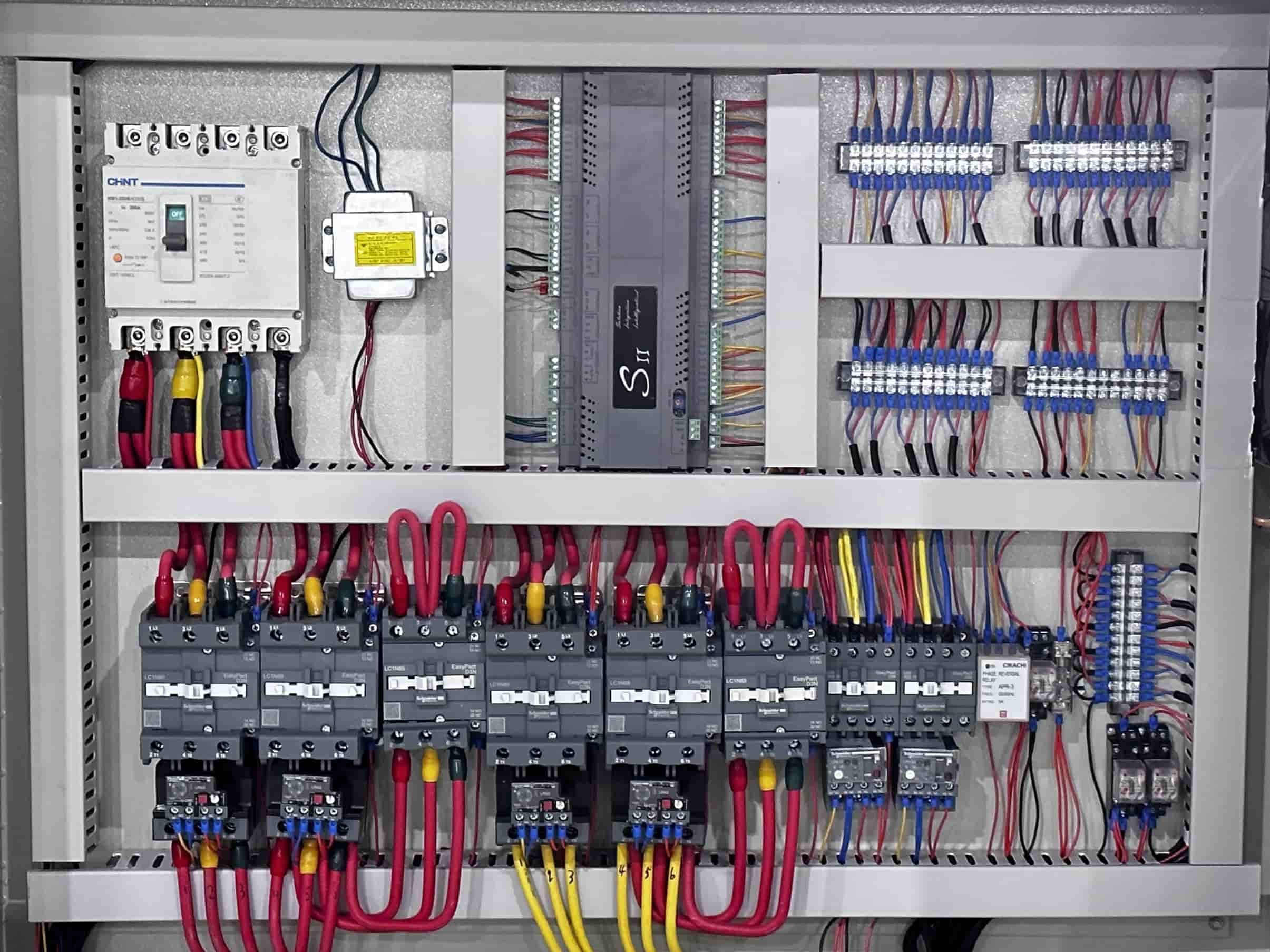

✅8-Inch PLC Touch Panel: Equipped with a high-definition touch operation panel, equipped with a customized control system, supports one-click setting of parameters, with a simple and intuitive interface, sensitive response, and convenient and efficient operation.

✅RS485 Remote Control: Supports customized communication modules, can be seamlessly connected to the factory automation system, realizes remote monitoring of equipment operation status, parameter adjustment, and multi-unit linkage control, helps industrial intelligent upgrade, and meets the control needs of different scenarios.

Product Detail Display

BRAND COMPRESSOR

Stable Operation and Long-Lasting Durability

5~30°C Temperature Control Range ±1°C Stable Constant Temperature

Use Fusheng/Hanzhong brand semi-enclosed screw compressor,

low noise, energy saving, and power saving.

ORIGINAL BRAND PARTS

The chiller's electrical control parts are all assembled with brand accessories.

Durable and stable in operation.

FULLY ENCLOSED WATER FLOW SWITCH

Cut off the compressor current to protect the freezer and the entire system from damage.

▶Yes, we are a manufacturer with over 10 years of experience.

2) How can I place an order?

▶You can contact us by email about your order details or place an order online.

3) What's the order procedure?

▶We issue you a Proforma Invoice after you confirm the order. And then you pay the deposit before we go into production. It usually takes 7-15 days for production. We will contact you for shipment details and the balance payment when the machine is ready. After payment has been settled, we will ship out the machine.

4) How can I pay you?

▶You can make payment by T/T (telegraphic transfer), Western Union, Moneygram, and L/C.

5) Do you have a manual for the machine?

▶Yes, of course. It is in the English version. We will send it with the machine.

6) Can you offer us the necessary paperwork for customs clearance?

▶Yes, of course. We will send you all the papers you need.

Copyright @2024 Pengqiang Intelligent Technology Group (Guangdong) Co., Ltd.

Network Supported

Network Supported